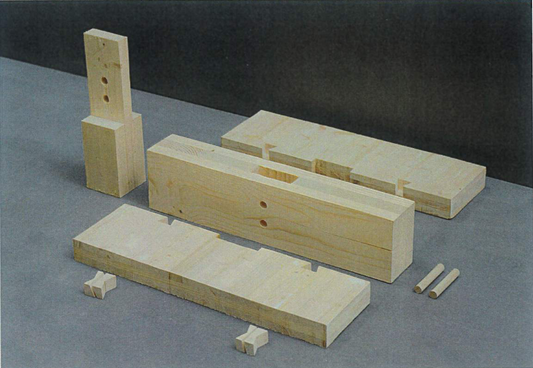

X-fix Holzverbinder!

hochbelastbar, - selbstspannend, - kostengünstig, - rückbaubar

X-fix Shop

Preisvorteile bei größeren Mengen nutzen!

X-fix Referenzen und Projekte

Alle anzeigenNews

Alle anzeigen-

Hasletre gewinnt den norwegischen Holzbaupreis ...

Oslotre gewinnt mit dem 3000 m² großen, vollständig rückbaubaren Bürogebäude Hasletre den norwegischen Holzbaupreis 2022.

Hasletre gewinnt den norwegischen Holzbaupreis ...

Oslotre gewinnt mit dem 3000 m² großen, vollständig rückbaubaren Bürogebäude Hasletre den norwegischen Holzbaupreis 2022.

-

„Haus des Holzes“ von Pirmin Jung mit X-fix

In Sursee/CH entsteht ein Dienstleistungs- und Wohngebäude aus Holz als Vorzeigeobjekt für digitales Bauen mit Holz.

„Haus des Holzes“ von Pirmin Jung mit X-fix

In Sursee/CH entsteht ein Dienstleistungs- und Wohngebäude aus Holz als Vorzeigeobjekt für digitales Bauen mit Holz.

-

X-Fix beflügelt das Wachstum von Fertighaushers...

Seit Anfang 2023 verwendet nun Multicomfort X-fix als Hauptverbindungsmittel und Schlüsselkompone

X-Fix beflügelt das Wachstum von Fertighaushers...

Seit Anfang 2023 verwendet nun Multicomfort X-fix als Hauptverbindungsmittel und Schlüsselkompone

-

X-Fix mini mit Frässchablone auf der BAU in Mün...

Ligna Tool Frässchablone fräst auf der BAU in München X-fix mini

X-Fix mini mit Frässchablone auf der BAU in Mün...

Ligna Tool Frässchablone fräst auf der BAU in München X-fix mini

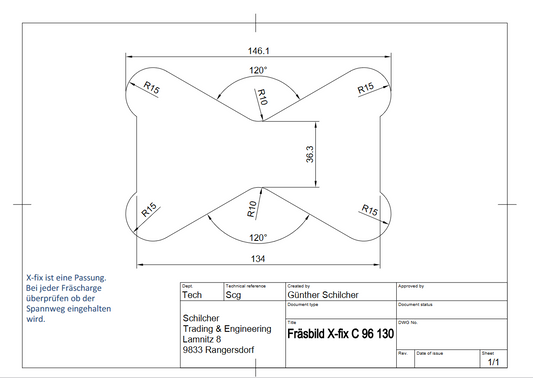

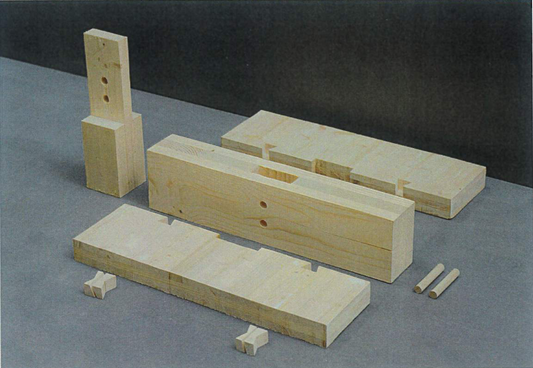

X-fix Technik

-

Forschungsprojekt: Entwicklung eines Voll-Holz-...

Die Öffentlichkeit hat im Zuge des Klimawandels erkannt, dass am Bau mit nachwachsenden Rohstoffen kein Weg vorbeiführt.

Forschungsprojekt: Entwicklung eines Voll-Holz-...

Die Öffentlichkeit hat im Zuge des Klimawandels erkannt, dass am Bau mit nachwachsenden Rohstoffen kein Weg vorbeiführt.

-

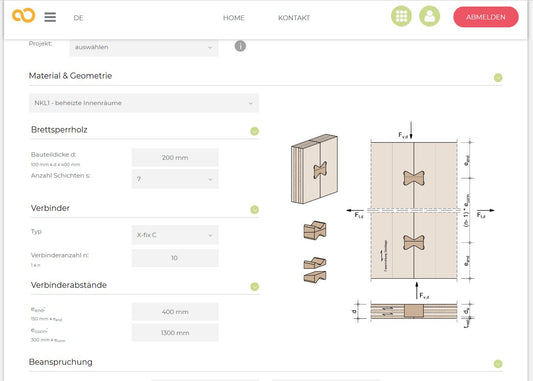

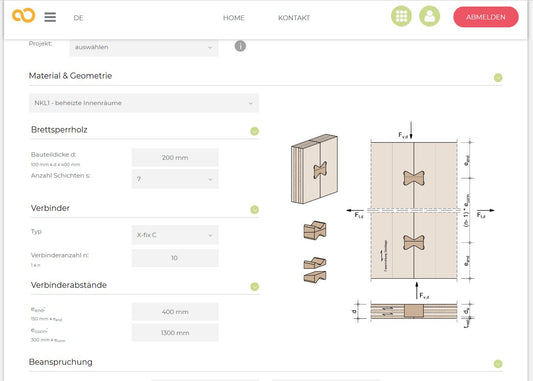

X-fix Statik Bemessungssoftware Ing-Tools für ...

Nach der Anmeldung bei www.ing-tools.de können Sie das Modul T11 zur Bemessung von X-fix C Verbindern dauerhaft kostenlos nutzen.

X-fix Statik Bemessungssoftware Ing-Tools für ...

Nach der Anmeldung bei www.ing-tools.de können Sie das Modul T11 zur Bemessung von X-fix C Verbindern dauerhaft kostenlos nutzen.

-

X-Fix mini mit Ligna Tool Schablone

In diesem Video wird gezeigt wie einfach die X-fix Ausfräsungen mit der neuen Lignatool X-fix mini Schablone hergestellt werden können.

X-Fix mini mit Ligna Tool Schablone

In diesem Video wird gezeigt wie einfach die X-fix Ausfräsungen mit der neuen Lignatool X-fix mini Schablone hergestellt werden können.