X-fix Holzverbinder!

hochbelastbar, - selbstspannend, - kostengünstig, - rückbaubar

X-fix Shop

Mengenrabatte verfügbar – sprechen Sie uns an!

News

Alle anzeigen-

Neo-Vernacular Kitchen (NVK): Die Zukunft des n...

Die Zukunft des nachhaltigen Wohnens nimmt in den Marken mit der Neo-Vernacular Kitchen (NVK) Gestalt an, einem innovativen Forschungsprojekt, das das Konzept des Wohnmoduls neu definiert. Ein toller Bericht von...

Neo-Vernacular Kitchen (NVK): Die Zukunft des n...

Die Zukunft des nachhaltigen Wohnens nimmt in den Marken mit der Neo-Vernacular Kitchen (NVK) Gestalt an, einem innovativen Forschungsprojekt, das das Konzept des Wohnmoduls neu definiert. Ein toller Bericht von...

-

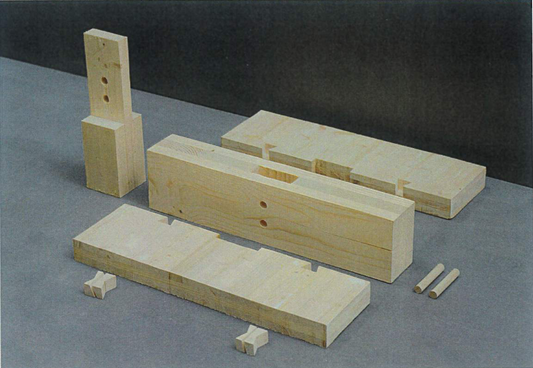

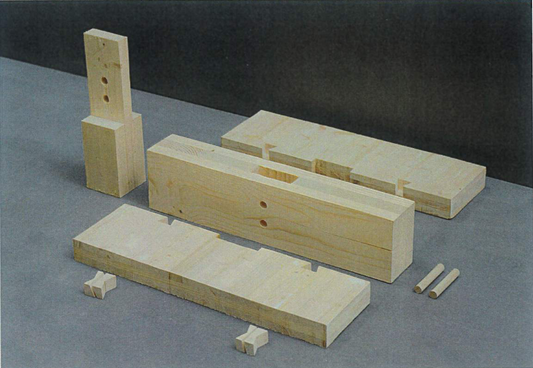

Prototyp für eine modulare Bodenplatte aus CLT-...

Im Rahmen einer Vertiefungsarbeit in Technologie und Architektur wurde bei Gramazio Kohler Research an der ETH Zürich ein Prototyp für eine modulare Bodenplatte aus CLT-Platten hergestellt. Die strukturelle Idee basiert...

Prototyp für eine modulare Bodenplatte aus CLT-...

Im Rahmen einer Vertiefungsarbeit in Technologie und Architektur wurde bei Gramazio Kohler Research an der ETH Zürich ein Prototyp für eine modulare Bodenplatte aus CLT-Platten hergestellt. Die strukturelle Idee basiert...

-

Projektbericht von G. Ungrund GmbH: Schnelle Sc...

Die G. Ungrund GmbH realisiert in Mönchengladbach ein Schulgebäude mit zwei Klassenräumen und zwei Differenzierungsräumen in Holzmassivbauweise. Die Aufstellung der insgesamt acht Module erfolgte innerhalb eines einzigen Tages. Dank des...

Projektbericht von G. Ungrund GmbH: Schnelle Sc...

Die G. Ungrund GmbH realisiert in Mönchengladbach ein Schulgebäude mit zwei Klassenräumen und zwei Differenzierungsräumen in Holzmassivbauweise. Die Aufstellung der insgesamt acht Module erfolgte innerhalb eines einzigen Tages. Dank des...

X-fix Technik

-

Forschungsprojekt: Entwicklung eines Voll-Holz-...

Die Öffentlichkeit hat im Zuge des Klimawandels erkannt, dass am Bau mit nachwachsenden Rohstoffen kein Weg vorbeiführt.

Forschungsprojekt: Entwicklung eines Voll-Holz-...

Die Öffentlichkeit hat im Zuge des Klimawandels erkannt, dass am Bau mit nachwachsenden Rohstoffen kein Weg vorbeiführt.

-

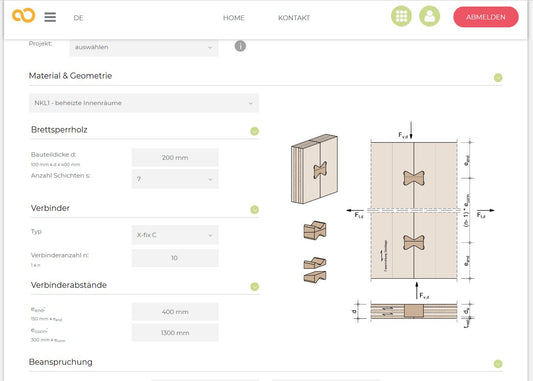

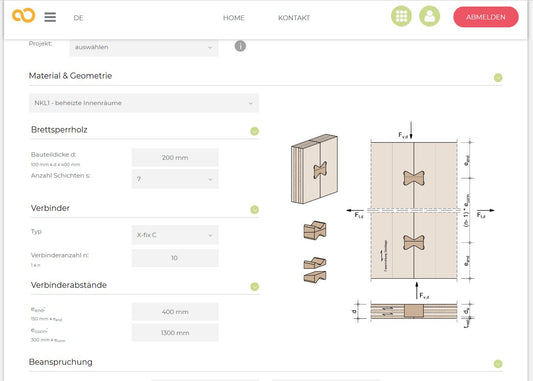

X-fix Statik Bemessungssoftware Ing-Tools für ...

Nach der Anmeldung bei www.ing-tools.de können Sie das Modul T11 zur Bemessung von X-fix C Verbindern dauerhaft kostenlos nutzen.

X-fix Statik Bemessungssoftware Ing-Tools für ...

Nach der Anmeldung bei www.ing-tools.de können Sie das Modul T11 zur Bemessung von X-fix C Verbindern dauerhaft kostenlos nutzen.

-

X-Fix mini mit Ligna Tool Schablone

In diesem Video wird gezeigt wie einfach die X-fix Ausfräsungen mit der neuen Lignatool X-fix mini Schablone hergestellt werden können.

X-Fix mini mit Ligna Tool Schablone

In diesem Video wird gezeigt wie einfach die X-fix Ausfräsungen mit der neuen Lignatool X-fix mini Schablone hergestellt werden können.