Frequently asked questions about the X-fix L wood-wood connection system

What is X-fix L?

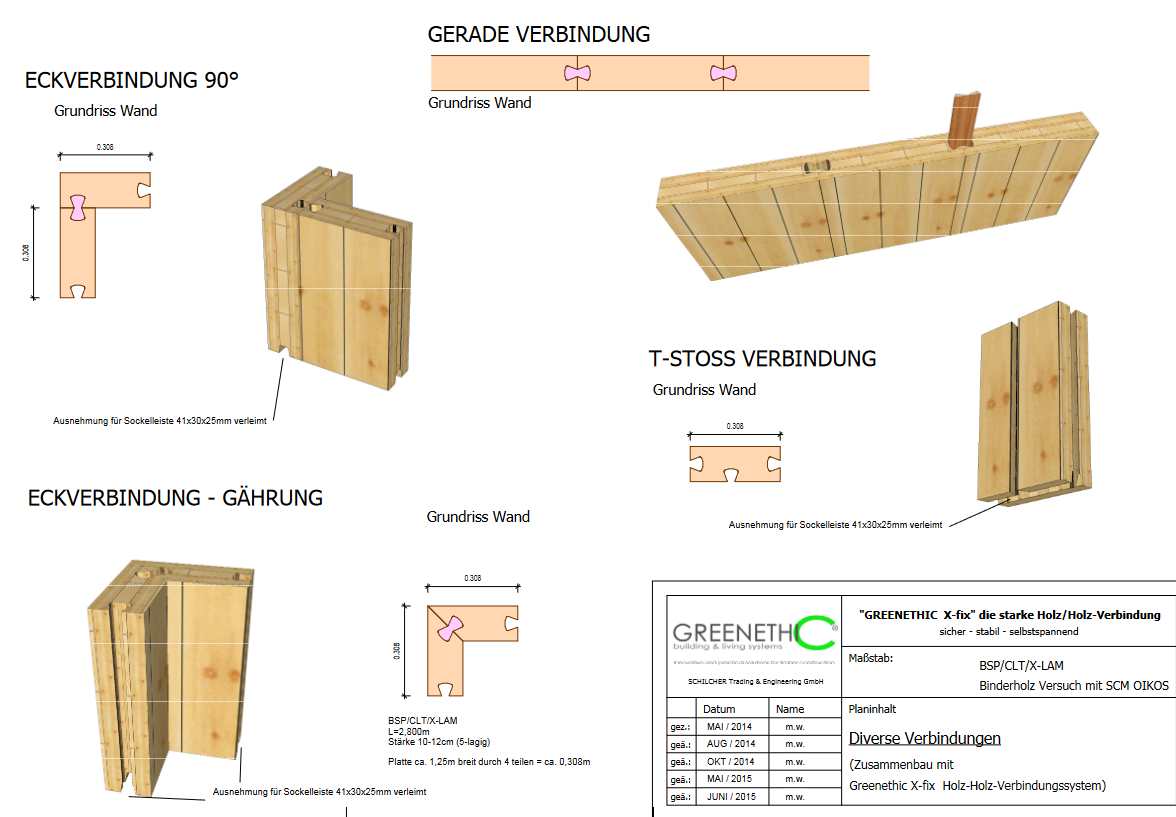

X-fix L is a linear timber-to-timber connector for upright CLT walls. With X-fix L, corner joints, T-joints and longitudinal joints of wall elements are possible, as well as the connection of complete building modules in the factory or on the construction site.

X- fix L consists of two dovetail-shaped and conically divided coupling strips with a maximum length of 3 meters. The dovetail-shaped grooves of the walls to be connected are placed in relation to each other and positioned correctly. The first part of the X-fix L coupling strip is inserted from above with the thick side first and falls into the cut-out.

The second part of the X-fix L is then inserted with the thin side first, falls quite easily into the cut-out until the two-sided conical connection fills the cut-out, is pushed in slightly by hand until only approx. 50 cm protrude. Then the second part of the X-fix L is carefully hammered in with a soft-face mallet until the wall elements are securely connected. The connection is complete!

Advantages of X-fix L?

Compared to conventional screw connections, X-fix L connects the components with a continuous, linear and form-fit wood-to-wood connection and has up to 300% greater strength than conventional screw connections. When assembling CLT wall elements, X-fix L is inserted into the connecting grooves from the inside of the wall.

In principle, no external scaffolding or working platform is required for the construction of a building shell, as X-fix L can be used from the inside of the building. The labor saving compared to screwing the walls from the outside of the building with wood screws is enormous and makes X-fix L a cost-effective connection system.

Application:

X-fix L is used for assembling corner joints (butt joints but also mitered joints), for T-joints and longitudinal joints of cross laminated timber wall elements. X-fix L is inserted and driven in from the inside of the building, so in principle no external scaffolding or working platform is required for the construction of a shell. The cost and time savings in the significantly easier handling of X-fix L compared to screwing the walls from the outside of the building with the corresponding wood screws certainly outweigh any additional costs of X-fix L.

For easier installation, we recommend lightly moistening the tapered cut surfaces of X-fix L with an appropriate adhesive. This allows the second clamping element to slide into the cut-out and the remaining clamping distance of approx. 30 - 50 cm can be easily hammered in with a soft-face hammer (approx. 2 kg). The hardened adhesive also provides additional security.

Examination & approval:

X-fix L was tested by holz.bau-forschungs GmbH at the Graz University of Technology and the corresponding design principles for the static calculations were also developed by DI Manfred Augustin.

The expert opinion was prepared by the Lignum Test Center (LTC) TU-Graz by Prof. Gerhard Schickhofer.

Types and milling patterns:

X-fix L 50/80/3000 --> PDF - milling image

Requirements for CLT panels and joinery:

To avoid misalignment of the wall connections, the thickness of the CLT panels must be calibrated (ground) before the X-fix grooves are milled. The X-fix L grooves must be milled on a suitable CNC machining center using the tools specified by X-fix . It is important that the workpieces are guided or clamped in a fixed position.

Videos